The Development of Water-Based Industrial Baking Paint

Amid the nation’s push for sustainable green development, water-soluble acrylic/polyester baking paints, with their eco-friendly properties and process advantages, are gaining growing competitiveness in the industrial coatings market, widely used in automotive, furniture, hardware parts, sports equipment and other fields.

Application Challenges of Pigment Pastes

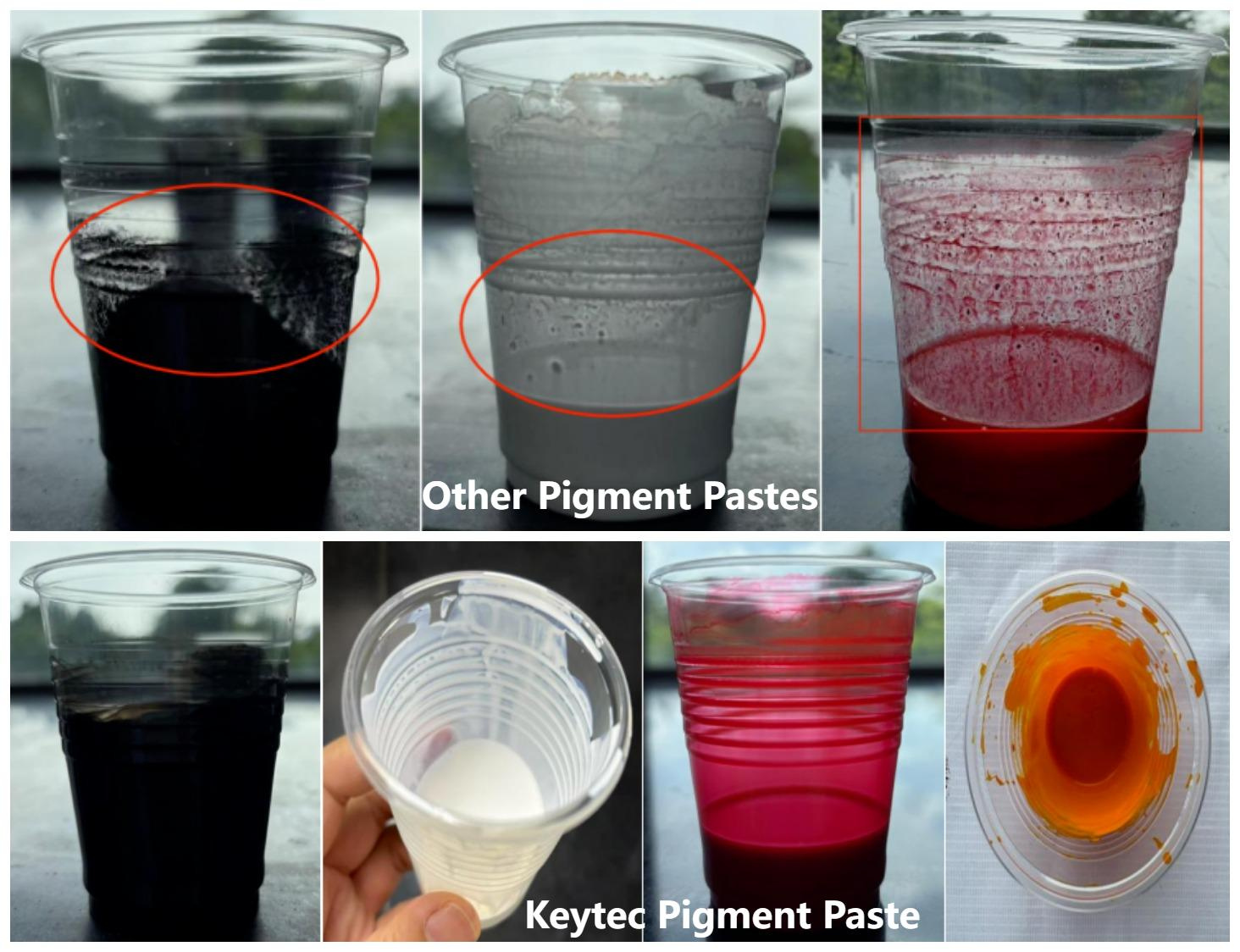

Due to the weak hydrophilicity of industrial baking paint resins, a large amount of alcohol ether cosolvents need to be added to improve system performance. However, when ordinary color pastes on the market are used in alcohol ether-containing systems, their incompatible properties easily cause problems like flocculation and coarsening, affecting the film-forming effect.

1. Alcohol Ether Resistance Performance Test

2. High-temperature Resistance Test

Generally, water-based baking paints require high-temperature baking (usually ≥120℃) to form a film, so the pigment pastes used must be able to withstand the baking temperature. Therefore, for pigment pastes applied in water-based baking paint systems, in addition to excellent alcohol-ether resistance, good compatibility and high-temperature resistance are also crucial. Keytec’s SI/TSI series pigment pastes, when tested in water-based baking paint binders from two different manufacturers, after being baked at 120℃ for 10 minutes, resulted in a complete and smooth paint film without blistering, particles, or discoloration compared to the unbaked state.

Post time: Jul-28-2025